Understand printing technology

In the printing industry, print finishing techniques are one of the key factors in producing high-quality printed products. Print finishing techniques use various processes and equipment to process and decorate printed materials to enhance their functionality, aesthetics, and protection. The following are several common print finishing techniques.

1. Offset Printing: This type of printing technology uses plates (made of aluminum) to transfer an image onto a rubber blanket. Then, it rolls that image onto a sheet of paper. This is called offset because here ink is not directly transferred to the sheet. This type of printing is ideal when larger quantities are needed.

2. Digital Printing: Like offset printing, this type of printing doesn’t use plates rather it uses a toner or larger printers which do use liquid ink. Digital printing is ideal when lower quantities are required. Digital printing equipment is less expensive as compared to offset printing equipment. Moreover, the setup cost is also much lower for digital printing for short runs.

If you are thinking digital printing vs offset printing which one should be ideal for your promotional campaign, always consider the quantity that you need to run your campaign. If you need only 100 flyers or 50 brochures, then digital printing will give you immense benefit in this regard. Offset printing is good only if the quantity is higher.

Print Finishing Techniques

1. Cutting and Folding/Binding

Sometimes, printed materials need to be cut and creased after printing so that they can be folded easily. This is the process of folding and assembling printed materials into multi-page booklets or books. This process makes printed materials more portable, easier to read, and can enhance the professionalism of printed materials.

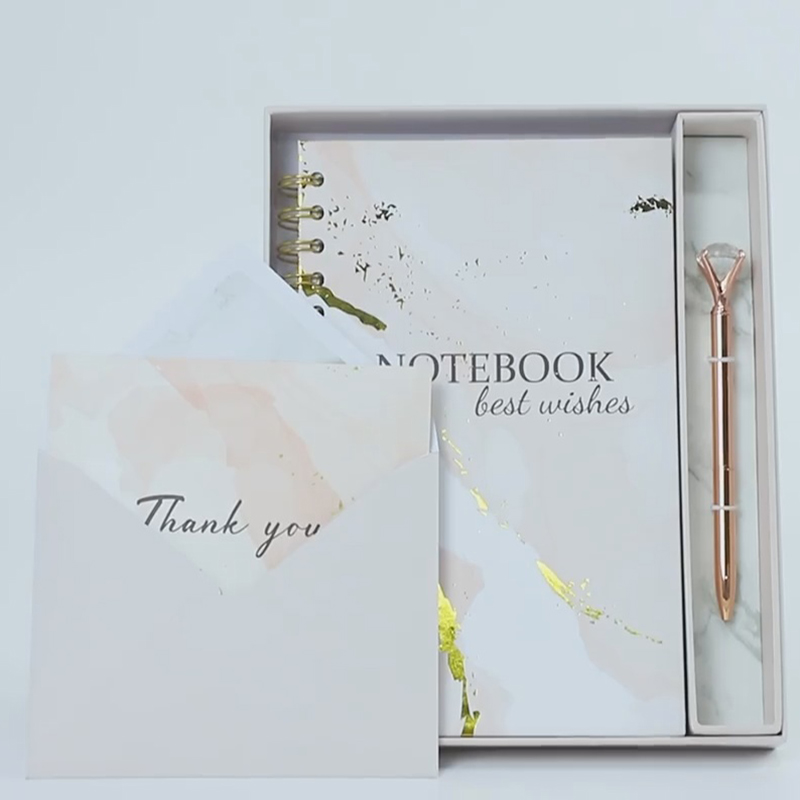

2. Foil Stamping

This is a surface decorative technique for printed materials. By adding metallic foil to printed materials, it gives them a sense of value and a luxurious feel. This technique is commonly used for book covers, business cards, and other projects that require special decoration.

3. Lamination

This is the process of attaching a layer of transparent or colored film to the surface of printed materials. This can protect printed materials from the effects of moisture, stains, and abrasion, and can also increase the stability and texture of printed materials.

4. UV Coating

This technique enhances the resistance of printed materials to natural factors such as humidity and light by adding a layer of UV coating on the surface of printed materials. This coating not only increases the gloss and texture of printed materials but also prevents them from discoloring, fading, or cracking.

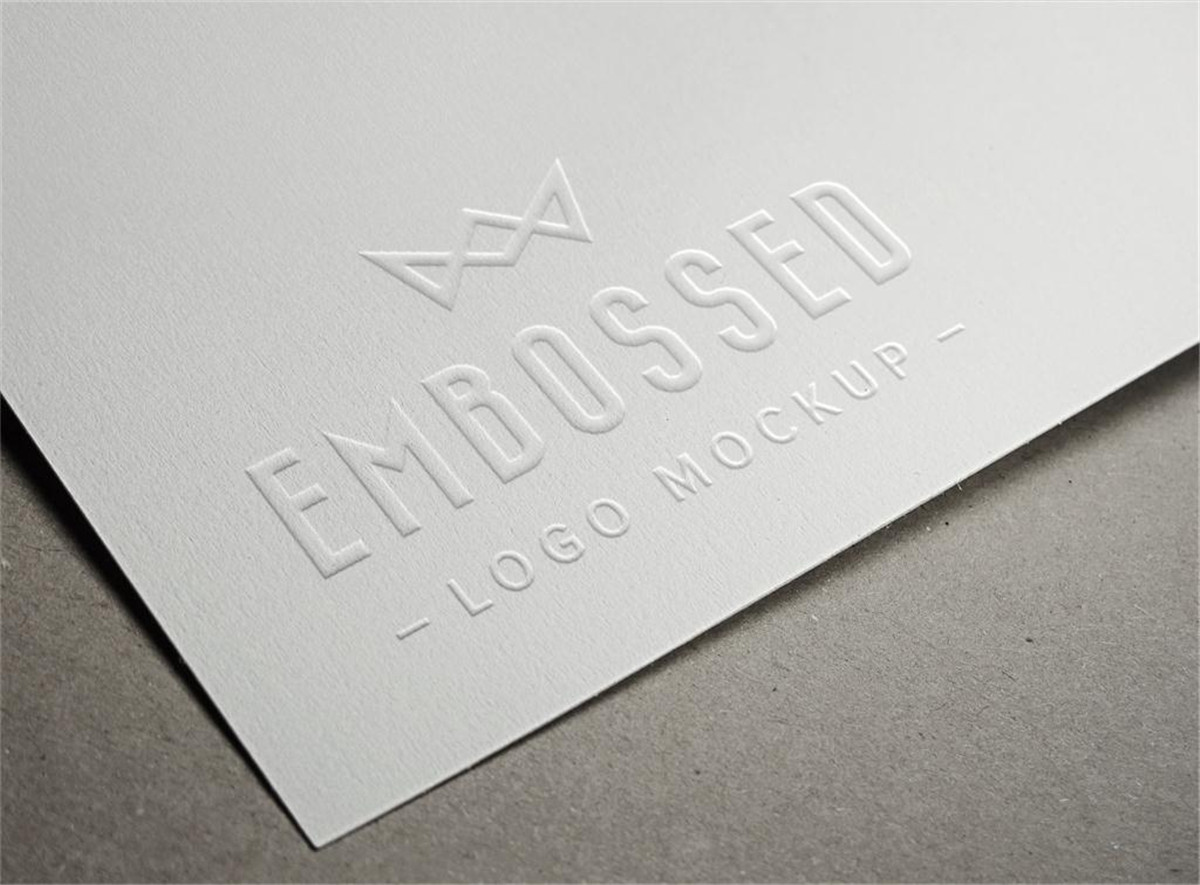

5. Embossing/ Debossing

Embossing is a type of finishing where you need to raise some parts of the printed page for emphasis and texture. By using embossing, you can enhance your print with amazing 3-d effects. Embossing is generally applied in conjunction with other techniques like foil stamping or spot UV lamination. Embossing adds a tactile dimension to your printed material. Now, your clients can feel all the images and texts properly. So, in a nutshell, embossing is the stamping of a design into a paper or card. This design produces a raised effect on the material. The same goes for debossing.

In summary, print finishing techniques are an indispensable part of the printing industry. They can add aesthetics, protection, and usefulness to printed materials. By using appropriate print finishing techniques, high-quality printed materials can be produced.